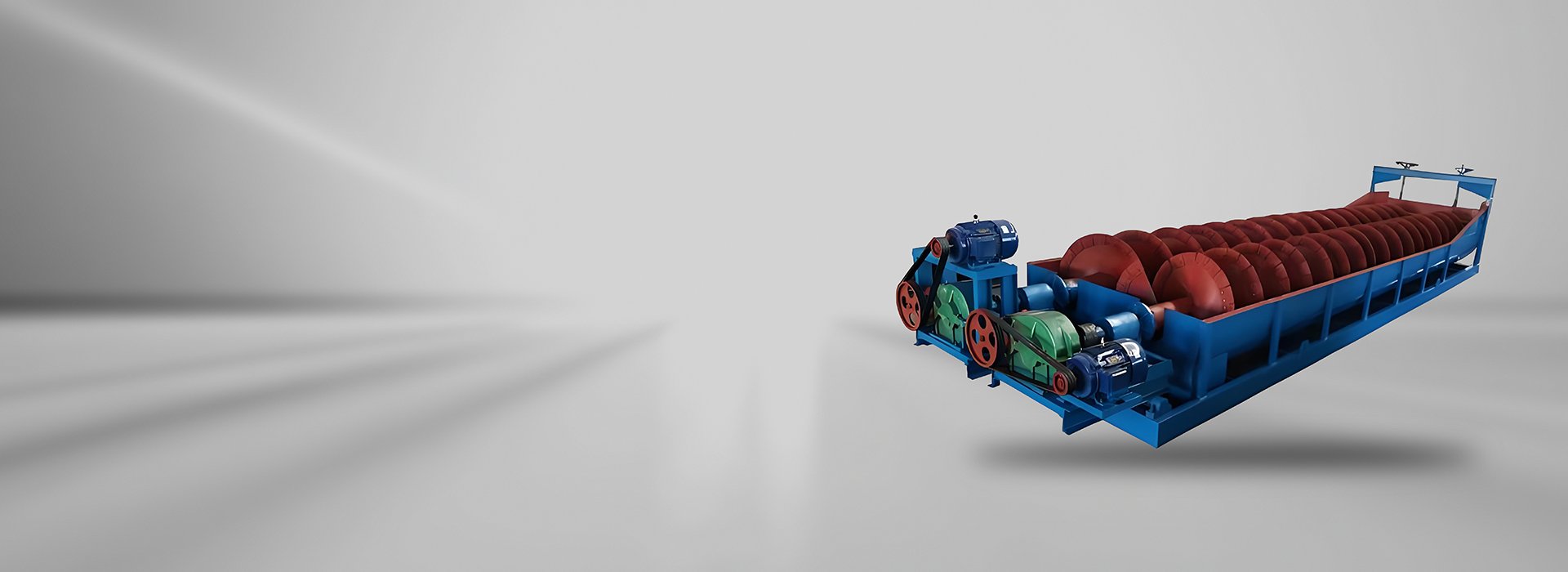

Your Expert Spiral Classifier Manufacturer in China

Sandreck, a professional spiral classifier manufacturer based in China with global operations, is a major manufacturer and supplier specializing in mineral processing equipment.

Our spiral classifiers are used in mineral processing to separate slurries by particle size. They are widely used for classifying metals (iron ore, tungsten ore) and non-metallic minerals, removing coarse sand, and slurry size classification. They also excel in ore settling particle size control and seed recovery.

We customize spiral classifiers to your specific needs: whether you are beneficiating metal ores (iron, copper, lithium), grading construction aggregates, or environmentally friendly tailings treatment, we have the right model for you.

Sandreck offers single and double spiral designs, high weir classifiers for coarse particle classification, and decanter centrifuge classifiers for fine particle classification, all of which help you achieve precise particle separation.

Product By Features

It has a small structure and low cost it can be used in small-sized and medium~sized mineral processing miners.

With it’s strong, durable construction set up is simple and it can be easily constructed and even operated by a single person with little .

With a higher settling pool and higher settling depth, this. is good for classifying the fine material (-100 to -200 mesh).

High Weir Spiral Classifier. It is employed in classification, and de-slime of large quantities of fine iron ore (-20 to +100 mesh).

Spiral Classifier Advantages

Based on the spiral rotating chute, the synergistic effect’s gravity and water on the separation efficiency of Spiral Classifier is maximized.

The wear of the spiral blades, shell and trough body is greatly reduced, and the spiral blades are lined with high manganese steel and wear-resistant plates.

Sandreck Spiral Classifier has a slotted design, so it is easy to discharge the equipment parts maintenance and make it less downtime.

The lifting mechanism can adjust the spiral height and flexibly adapt to the needs of slurries of different concentrations and different particle sizes.

The low-speed and high-torque transmission system runs smoothly, and the power consumption is 60%-70% of similar equipment.

As a large-scale equipment manufacturer. The spiral classifier is sold to customers at a standard price.

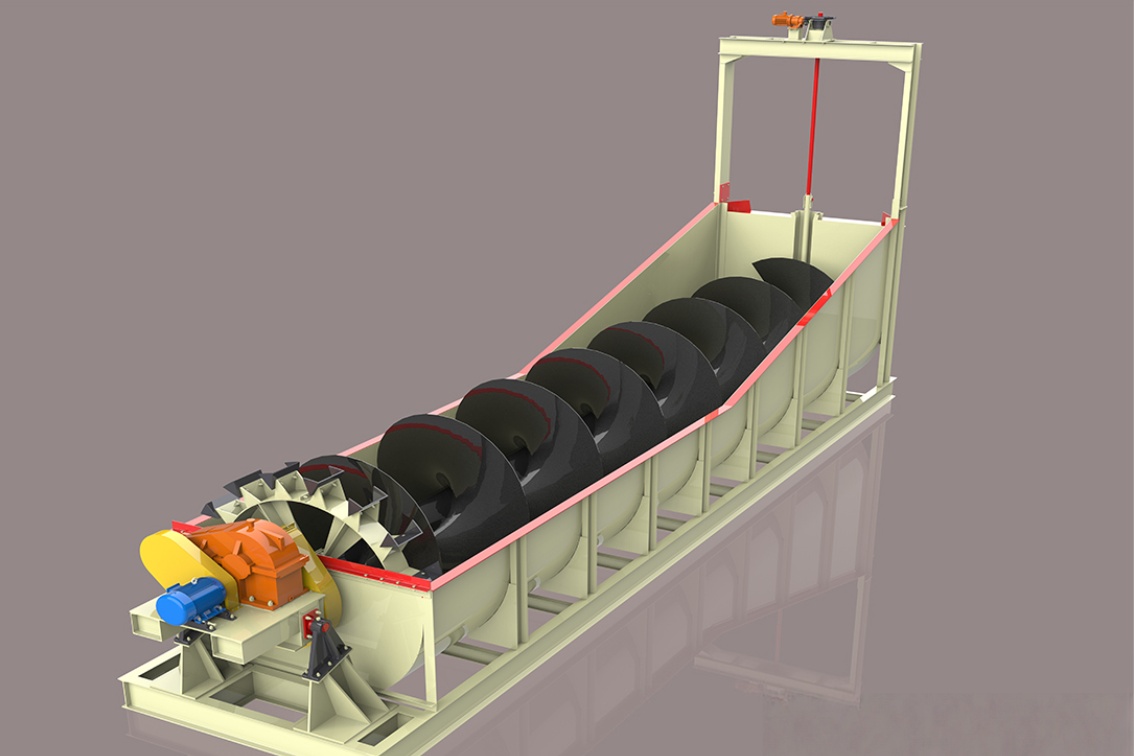

Modular Design

Sandreck employs a modular design, precision-engineering the Spiral Classifier body into independent modules like the tank and spiral assembly.

This not only standardizes production but also enables you to perform maintenance and part replacements as easily as working with building blocks.

The result is significantly reduced downtime and guaranteed continuous operation for your plant.

Intelligent Anti-Clogging Lifting System

We understand the startup challenges caused by settled sands. Sandreck’s Spiral Classifier features an intelligent lifting system.

With a simple one-button operation during shutdown, the spiral is effortlessly raised, fundamentally eliminating the risk of “machine burying” and protecting your motor and drive system from damage.

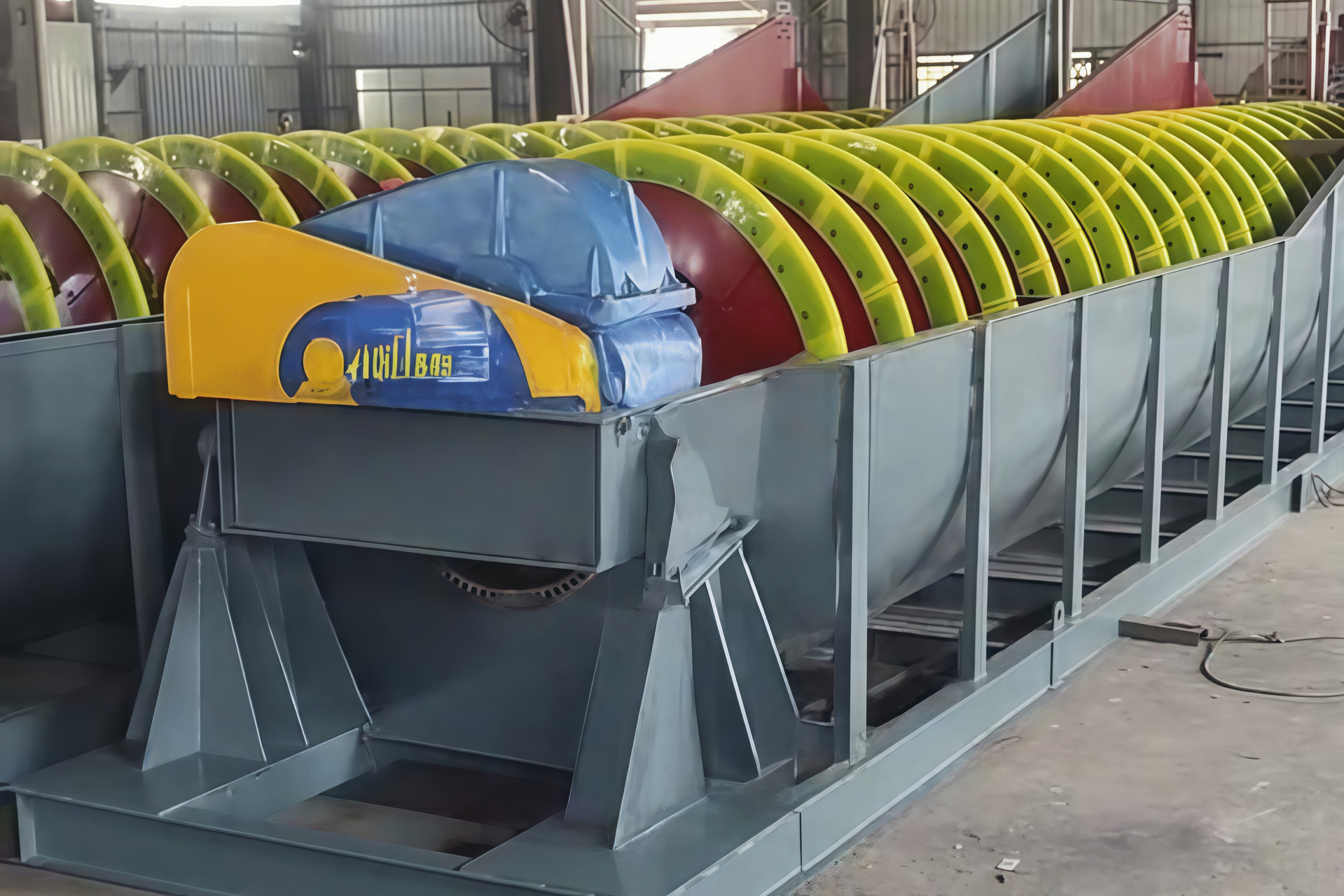

Armor-Clad Core Components

When it comes to wear resistance, Sandreck Spiral Classifier doesn’t cut corners.

We apply specialized wear-resistant composite materials to key areas including the spiral blades, main shaft, and tank liner.

It’s like equipping the machine with protective armor, directly reducing wear for you, extending service life, and lowering your total cost of ownership.

How does a spiral classifier work?

A spiral classifier is like a “smart sieve” for ore slurry. Its ingenious mechanical structure automatically separates the ground slurry into two parts:

Coarse particles sink to the bottom (return sand) and fine particles overflow (overflow).

This not only prepares the slurry for the next separation step but also returns unqualified coarse sand to the mill for further grinding, making it an indispensable aid in the grinding circuit.

Why Choose A Sandreck Spiral Classifier?

With so many options on the market, why trust Sandreck?

Sandreck spiral graders utilize a modular manufacturing process, where the main body is broken down into modules—the trough, spiral assembly, and control system—that are manufactured separately and then precisely assembled. This not only minimizes manufacturing errors but also shortens installation time (installation can be completed within 3 days).

Our spiral classifiers offer an optional intelligent lifting system that allows the spiral to be raised with a single click during downtime, preventing sand from burying the classifier and preventing it from starting. This protects the equipment and saves time and effort.

Sandreck understands that every mine’s ore is unique. We offer professional selection services and can customize our spiral classifier to your specific needs, ensuring it perfectly matches your production line.

More About Our Company

- Technical Parameters

Model | Screw Diameter (mm) | Sink Length (mm) | Screw RPM (r/min) | Capacity(t/d) | Power(kw) | Dimension L×W×H | ||

| Return Sand | Overflow | Drive | Lifting | |||||

| FLG-5 | 500 | 4500 | 8-12.5 | 135-210 | 32 | 1.1 | 5430×680×1480 | |

| FLG-7 | 750 | 5500 | 6-10 | 340-570 | 65 | 3 | 6720×980×1820 | |

| FLG-10 | 1000 | 6500 | 5-8 | 675-1080 | 110 | 5.5 | 7590×1240×2380 | |

| FLG-10 | 8400 | 675-1080 | 85 | 7.5 | 9600×1240×2680 | |||

| FLG-12 | 1200 | 6500 | 4-6 | 1170-1870 | 155 | 7.5 | 2.2 | 8180×1570×3110 |

| FLG-12 | 8400 | 1170-1870 | 120 | 7.5 | 2.2 | 10370×1540×3920 | ||

| FLG-15 | 1500 | 8300 | 4-6 | 1830-2740 | 235 | 7.5 | 2.2 | 10410×1880×4080 |

| FLG-15 | 10500 | 1830-2740 | 185 | 7.5 | 2.2 | 12670×1856×4180 | ||

| 2FLG-15 | 8300 | 2280-5480 | 470 | 15 | 4 | 10410×3390×4080 | ||

| 2FLG-15 | 10500 | 2280-5480 | 370 | 15 | 4 | 12670×3370×4890 | ||

| FLG-20 | 2000 | 8400 | 3.6-5.5 | 3290-5940 | 400 | 11-15 | 3 | 10790×2530×4490 |

| FLG-20 | 12900 | 3210-5940 | 320 | 15-18.5 | 3 | 15610×2530×4490 | ||

| 2FLG-20 | 8400 | 7780-1180 | 800 | 1 1 ( 2 tower ) | 5.5 | 11000×4600×4700 | ||

| 2FLG-20 | 12900 | 7780-1180 | 640 | 18.5(2tower) | 5.5 | 15760×4600×5640 | ||

| FLG-24 | 2400 | 9130 | 3.67 | 6800 | 580 | 22 | 3 | 11650×2910×4970 |

| FLG-24 | 14130 | 6800 | 490 | 22 | 4 | 16580×2930×7190 | ||

| 2FLG-24 | 9130 | 13600 | 1160 | 18.5(2tower) | 5.5 | 12710×5430×5690 | ||

| 2FLG-24 | 14130 | 13700 | 910 | 3 0 ( 2 tower ) | 7.5 | 17710×5430×8000 | ||

| FLG-30 | 3000 | 12500 | 2-4 | 11650 | 890 | 30 | 4 | 16020×3320×6350 |

| 2FLG-30 | 12500 | 23300 | 1785 | 3 0 ( 2 tower ) | 7.5 | 16020×6640×6350 | ||

| 2FLG-30 | 14300 | 23300 | 1410 | 3 0 ( 2 tower ) | 7.5 | 17091×6640×8680 | ||

Testimonials

Sandreck is a Spiral Classifier manufacturer, integrating manufacturing, production and supply in one. We have a professional after-sales team, there are original parts to provide, maintenance costs are very low.

Sandreck have a dedicated production team. The delivery time of our Spiral Classifier is generally made within 20 days after the contract is signed.

You can send us a message on WhatsApp(+86 +13666293477) or leave your contact details on our website,later our online customer service will contact you and offer the price of our Spiral Classifier.

Related Product

Linear feeding equipment that continuously feeds materials into the crusher.

Used for grading and screening in the fields of minerals, quarries, building materials, etc.

Cleans dirt and impurities from sand and gravel to improve the purity of final product.

Transfers materials between processes, connecting crushing, screening, washing, etc.