Magnetic Equipment

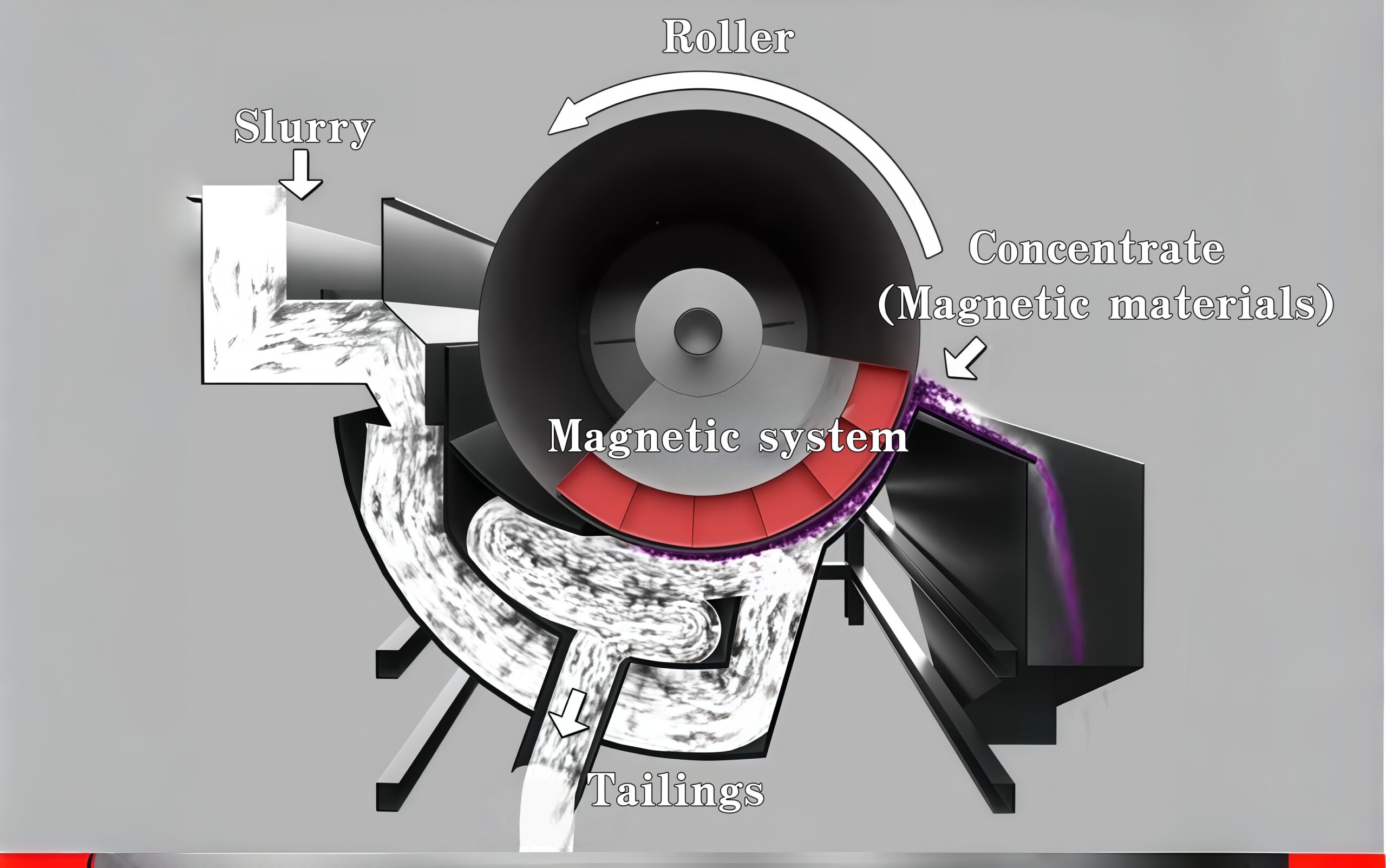

The magnetic separator is the “Expert in Magnetic Separation” in your mineral processing line, performing the all-important task of separating magnetic from non-magnetic minerals, which is made possible through a difference in magnetism of minerals.

![]() Ideal for mining, recycling, and industrial processing.

Ideal for mining, recycling, and industrial processing.

![]() Built for heavy-duty use with minimal maintenance requirements.

Built for heavy-duty use with minimal maintenance requirements.

![]() Lowers long-term expenses by improving productivity and reducing waste.

Lowers long-term expenses by improving productivity and reducing waste.

![]() Streamlines material sorting, reducing manual labor and operational time.

Streamlines material sorting, reducing manual labor and operational time.

Your Expert Magnetic Equipment Supplier in China

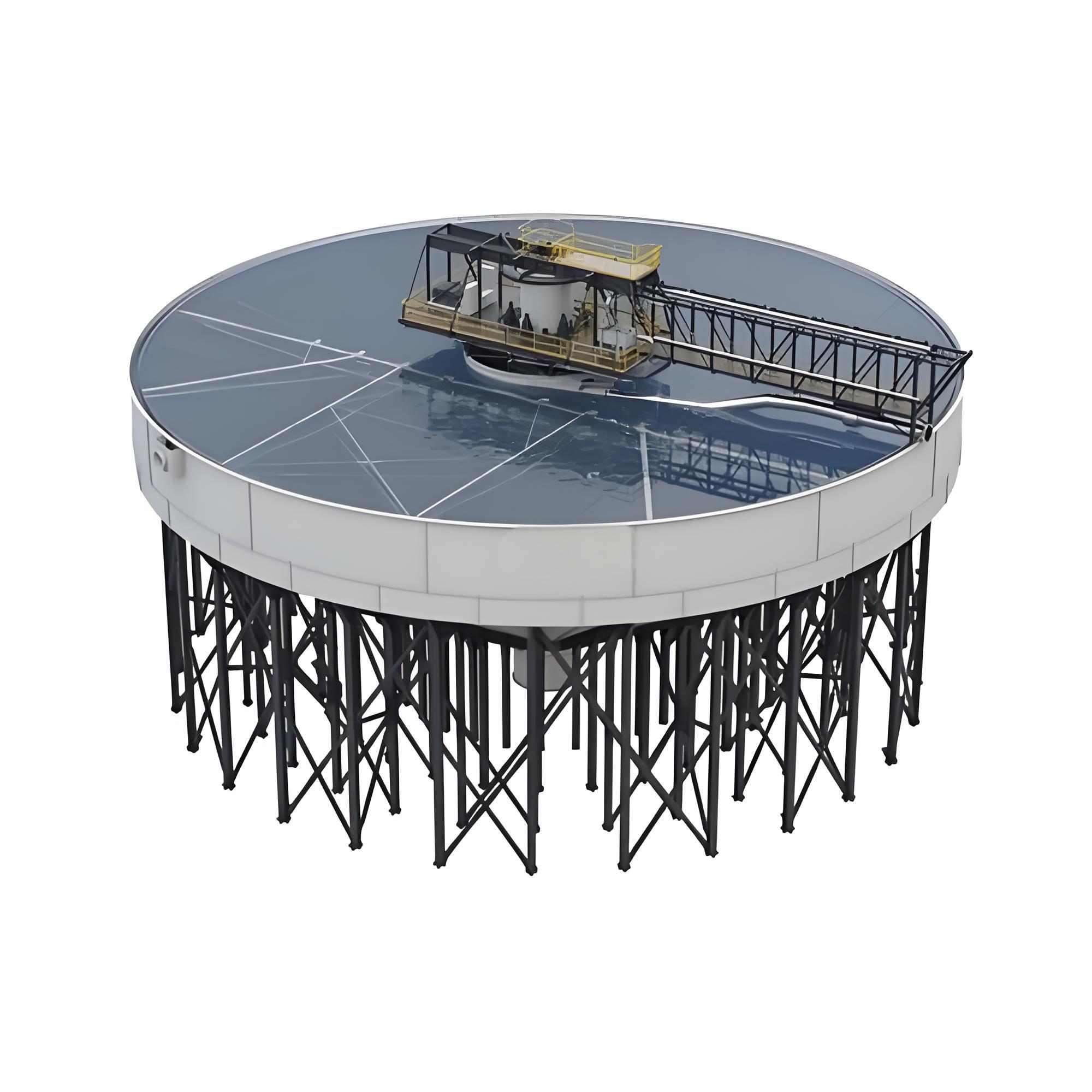

Are you looking for a high quality Magnetic Equipment to meet different sorting needs? As a professional mining machinery manufacturer in China, Sandreck Magnetic Equipment will be your best choice. Our Magnetic Separator is designed specifically for mineral sorting. It uses high-performance magnetic materials to create the magnetic system.

As a Magnetic Equipment source factory,the magnetic field strength of our device is high and the demagnetization rate is extremely low and the surface of the cylinder is covered with wear-resistant rubber and matched with non-magnetic stainless steel structure, which has a long service life.

As a major supplier of large-scale mining sand and gravel projects, Sandreck is also a professional magnetic separators manufacturer. Our factory sells a wide range of magnetic separators at affordable prices.

Product By Features

Minerals can be separated without water source, used for pre-selection of coarse-grained strong magnetic minerals.

Uses permanent magnets to build a magnetic system and is used to select strong magnetic minerals.

Pre-selection of coarse-grained strong magnetic minerals, cooperating with the built-in magnetic system.

Sandreck Magnetic Equipment Advantages

Adopts high magnetic energy product, high and stable magnetic field strength to ensure long-term sorting efficiency.

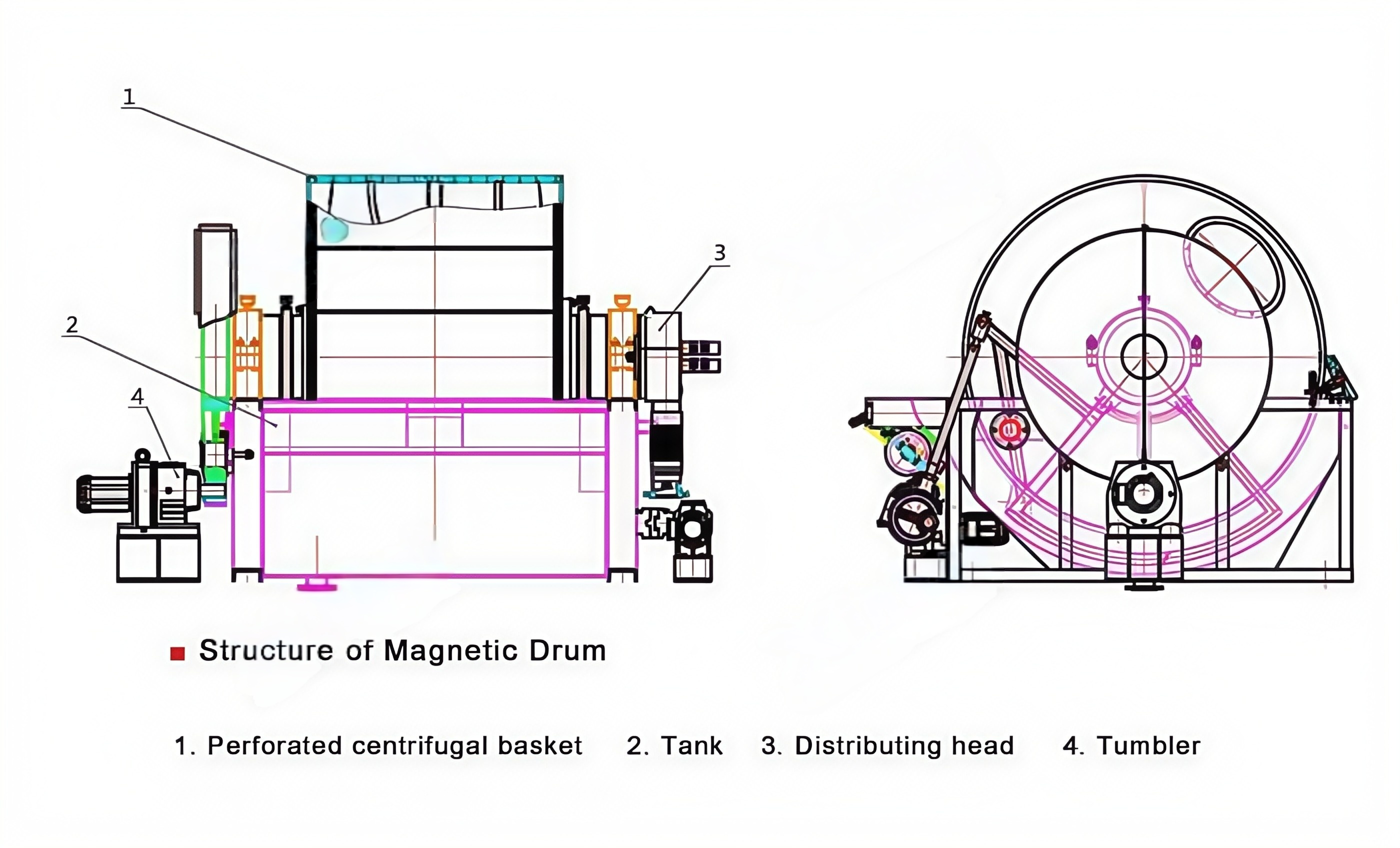

Magnetic Drum is wrapped with non-magnetic stainless steel to prevent falling off which suitable for high-intensity operations.

Field strength gradient magnetic system + large wrap angle design, more tailing 10%-30%, concentrate grade increased by 1%-8.7%.

Magnetic Drum is tolerant to fluctuations, stable in feed rate, particle size, and concentration, stable in production, and reduced downtime.

Solves the problems of eddy current heating in conventional equipment, and improves the sorting smoothness and reliability.

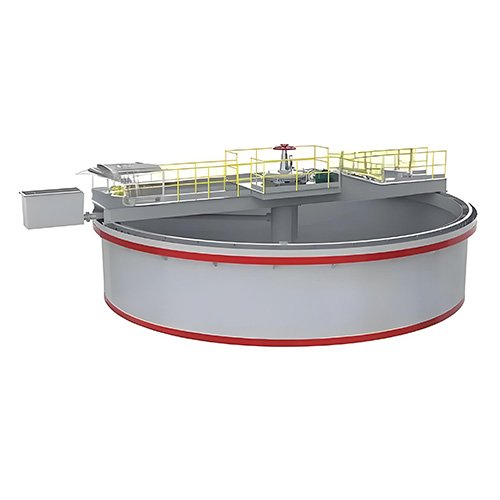

Magnetic Separator, Customizable downstream/semi-countercurrent tanks to achieve high-quality mineral processing indicators.

Customized for Your Ore

For minerals with a weak magnetic properties, such as the hematite, we have high intensity magnetic separators with magnetic forces in the range of 18,000 to 22,000 gauss.

For ultra-fine powders (<0.005mm) we have available high gradient matrix type magnetic separators.

For slurries at elevated temperatures, we have optional N52SH high thermal resistant, stable operation magnetic materials.

Climate-Adapted Solutions

For different climate conditions, Sandreck Equipment can be equipped with specialized protection systems: high-temperature resistance systems for tropical regions and anti-freeze modules for cold areas.

Magnetic Equipmentr: Your Expert in Magnetic Mineral Separation

Magnetic Equipment is essential for the purification of minerals and also for the recovery of resources.

Sandreck Magnetic Separators are ideal for:

Metal Ore beneficiation: Concentration of magnetic minerals such as magnetite and ilmenite.

Purification of non-metallic ores: Iron removal and purification of materials such as quartz, feldspar and kaolin.

Resource recycling: Recovery of valuable materials from solid waste resources such as steel slag and fly ash.

Industrial protection: Iron removal protection for the raw materials used in such industries as ceramics and glass.

Smart Equipment Integration

If your production line requires coordinated operation with ball mills, flotation machines, thickeners, or jig separators, Sandreck offers customized intelligent linkage control systems to achieve precise capacity matching.

When processing iron or manganese ore, the ball mill first grinds material to 1-5mm, with slurry directly fed to the magnetic separator.

For iron-copper ore, the magnetic separator first recovers iron concentrate, with non-magnetic slurry proceeding to flotation for copper recovery.

Both magnetic separator concentrate and tailing can be sent to a thickener (increasing density from 20% to 60%) before filtration reduces moisture to ≤15%.

For >5mm magnetite ore, the jig first removes over 70% waste rock before rough concentrate enters the magnetic separator. This reduces separator load, increases throughput by 30%, and decreases wear part consumption.

Testimonials

Regularly clean the minerals adhering to the surface of the cylinder; pay attention to the thickness and replace it in time; test the magnetic field strength every six months.

There are mainly dry magnetic separators, magnetic separators and magnetic drums.

Of course! Common combination schemes are:

- Magnetic separation + flotation, first magnetic separation to recover magnetic minerals, and then flotation to extract non-magnetic valuable components.

- Magnetic separation + gravity separation, used for graded recovery of complex paragenetic ores.