Mineral Processing Equipment

Mineral processing equipment is essential for efficiently extracting and refining valuable minerals from raw ore.

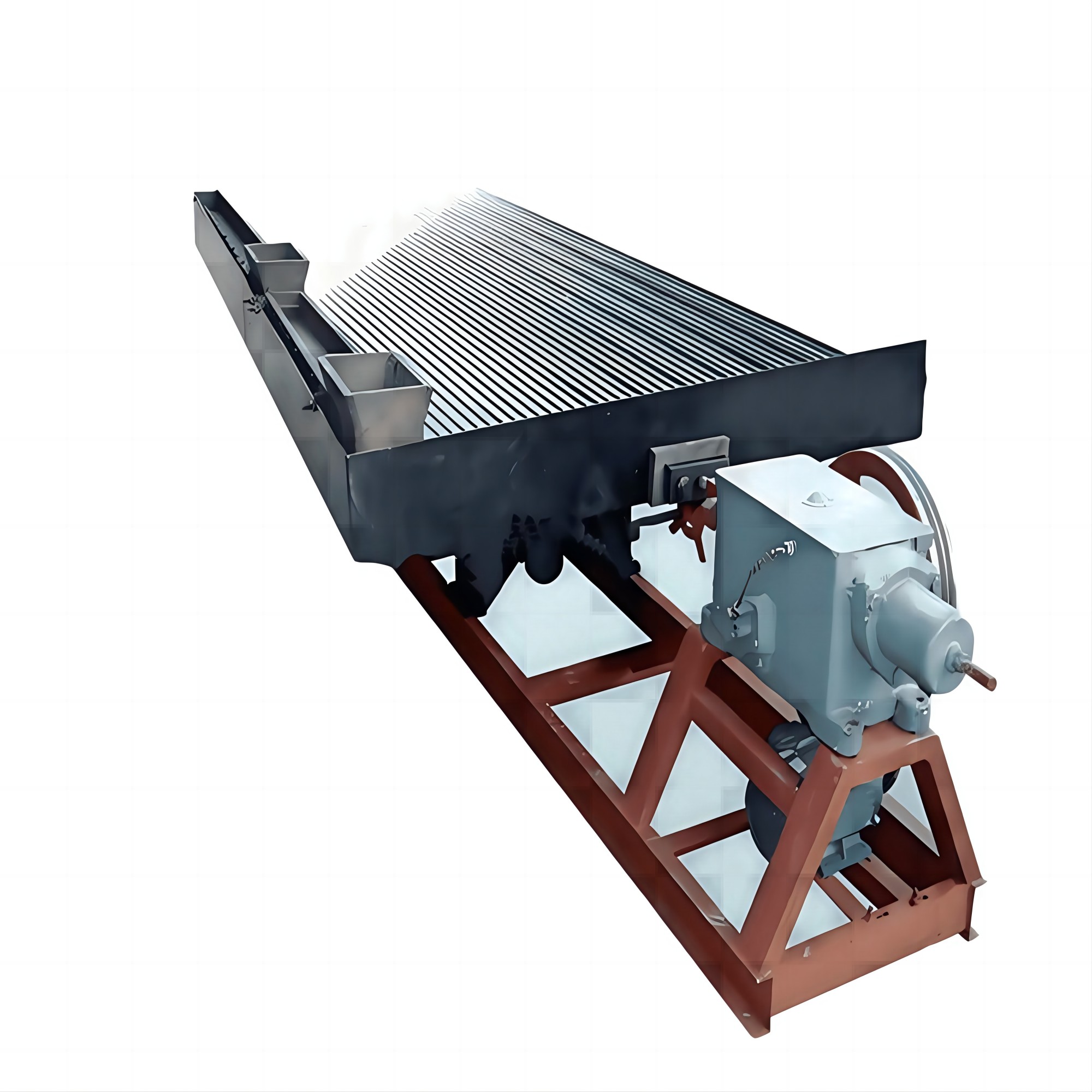

![]() Built with robust materials to withstand harsh operating conditions.

Built with robust materials to withstand harsh operating conditions.

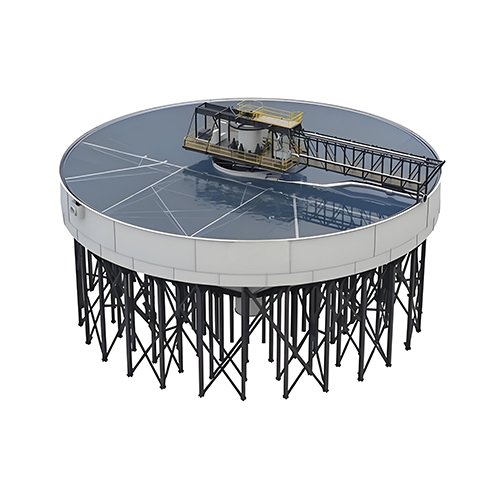

![]() Modern systems use smart controls for accurate separation and processing.

Modern systems use smart controls for accurate separation and processing.

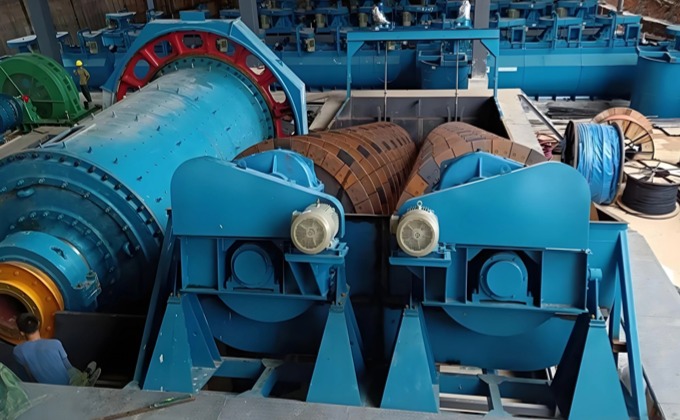

![]() Advanced designs maximize mineral recovery while minimizing energy consumption.

Advanced designs maximize mineral recovery while minimizing energy consumption.

Your Mineral Processing Equipment Supplier in China

Sandreck’s beneficiation equipment is used by international mining giants around the world and is designed for copper and gold as well as iron ore and rare earths, and our solutions lead the industry in providing highly efficient products for both wet and dry beneficiation applications.

SandRock’s mineral processing equipment can be categorized into a number of one-time processing packages such as crushers, mills, screening equipment, etc., in addition to the main material processing equipment.

Sanreck Heavy Industries is one of the mineral processing service brands based in China, specializing in mineral processing consulting, design, process flow design, equipment procurement and production, construction and installation equipment integration.

Sandreck is a Mineral Processing Equipment manufacturer in China, which integrates mineral processing process consulting, customized mineral processing solutions, equipment manufacturing and procurement, engineering construction, installation and commissioning.

Product By Features

Efficient separation equipment for fine-grained minerals with high quality.

Used for separation of materials with different densities.

Sandreck Mineral Processing Equipment Advantages

Absorb advanced technology at home and abroad to optimize the structure of our Mineral Processing Equipment, making it more efficient.

Mineral Processing Equipment can process a variety of minerals, such as gold, iron ore, limestone, marble, coal, ceramics and so on.

We are a professional Mineral Processing Equipment manufacturer, our Mineral Processing Equipment price is at the lowest price.

Sandreck has a professional team to provide you with pre-sales, sale, after-sales one-stop service, ensuring your project proceeding smoothly.

The production process is clear and transparent, and each process is strictly controlled by professional quality inspection.

Professional production and transportation team, can be delivered within 25 working days after the contract is signed.

Professional Mineral Processing Equipment Manufacturer

Sandreck Mining Company has its own mineral processing laboratory to help you conduct mineral processing experiments and match the best processing proposal for your project.

EPC Mineral Dressing General Contracting Service

Mature contracting and construction of three types of production lines:

- Aggregate processing: 100-3000 tons aggregate production line

- Mineral processing: metal/non-metallic mineral processing production line

- Coal quality improvement: coal washing/coal gangue comprehensive utilization production line

Mineral Processing Equipment Manufacturer, Be Your Trusted Partner

Sandreck is a full–service company engaged in research, development, design, and manufacturing of Mineral Processing Equipment. We have more than 100 pieces of advanced machining equipment, from CNC vertical lathes to laser cutting machines, which gives us a great platform to offer timely and high quality production.

Our core values extend beyond the manufacturing process of Mineral Processing Machines. We are a reliable partner providing customized professional solutions and advanced support designs to our customers around the world to achieve the best return on investment and production efficiency.

Sandreck Mineral Processing Equipment Customization Service

We customize the procedures (crushing, grinding, sorting) for your ore sample, to achieve exacting match and maximum efficiency of operation from the very beginning.

We provide designs of mMineral Processing Equipment and modular configurations, fit to your production capacity and space requirement. We can ultimately change both the structure and functionality of the concentrator based on

Sandreck Mineral Processing Equipment allows flexible and adaptable configurations, including even basic level automation to complete intelligent systems, upgrade it to AI optimized systems based on needs, with continuous improvement to production efficiency.

We provide full lifecycle support for the Mineral Processing Equipment we sell, including installation training, an annual inspection of equipment, and spare parts inventory, plus we adapt to local environments and regulations to achieve long term applications of stable and reliable operations.

Mineral Processing Equipment Cases

As a well-known integrated supplier of mineral processing equipment and solutions in China, Sandreck has grown into a solid support for the stable operation of thousands of mineral processing companies.

Processing material: Perspex

Capacity: 300-1000TPD

Process flow: Coarse Crushing – Fine Crushing – a Section of Grinding – Roughing – Coarse and Fine Regrinding – Selection – Fine Sweeping

Processing material: iron ore

Capacity: 1000t/d

Process flow: Coarse Crushing – Fine Crushing – a Section of Grinding – Roughing – Coarse and Fine Regrinding – Selection – Fine Sweeping

Testimonials

The common flotation processes are generally divided into three categories: preferential flotation, mixed flotation and semi-preferential mixed flotation.

Magnetic equipment is suitable for the separation of magnetic minerals (such as magnetite, ilmenite); The flotation equipment realizes the separation of fine non-magnetic minerals (such as gold, copper, lead-zinc ore) by chemical adsorption.

- Regular lubrication, bearings, gears and other moving parts according to the operation manual cycle replacement of special grease.

- Monitoring of wear parts, regularly monitoring the wear degree of equipment wearing parts, early warning replacement.

- Seasonal maintenance, moisture and rust prevention in rainy season, winter pipeline antifreeze protection.

You can send us a message via WhatApp (+86 13666293477) or leave your message on this page (click), our online customer service will get in touch with you ASAP.

Related Products

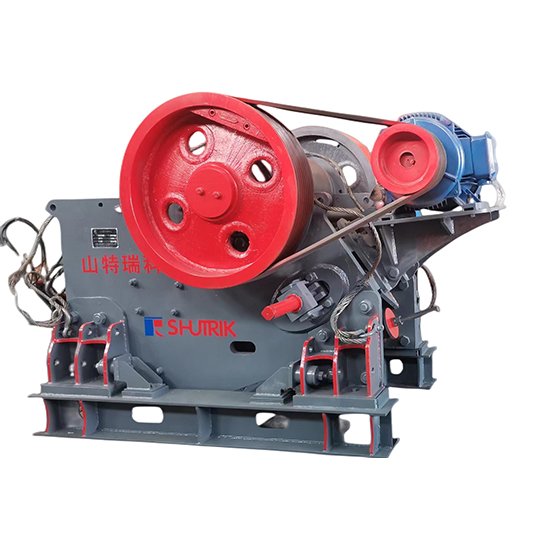

Jaw Crusher

Jaw CrusherSandreck Jaw Crusher is the first and primary choice for the coarse crushing.

A modular crushing equipment driven by tire chassis, integrating the whole process.