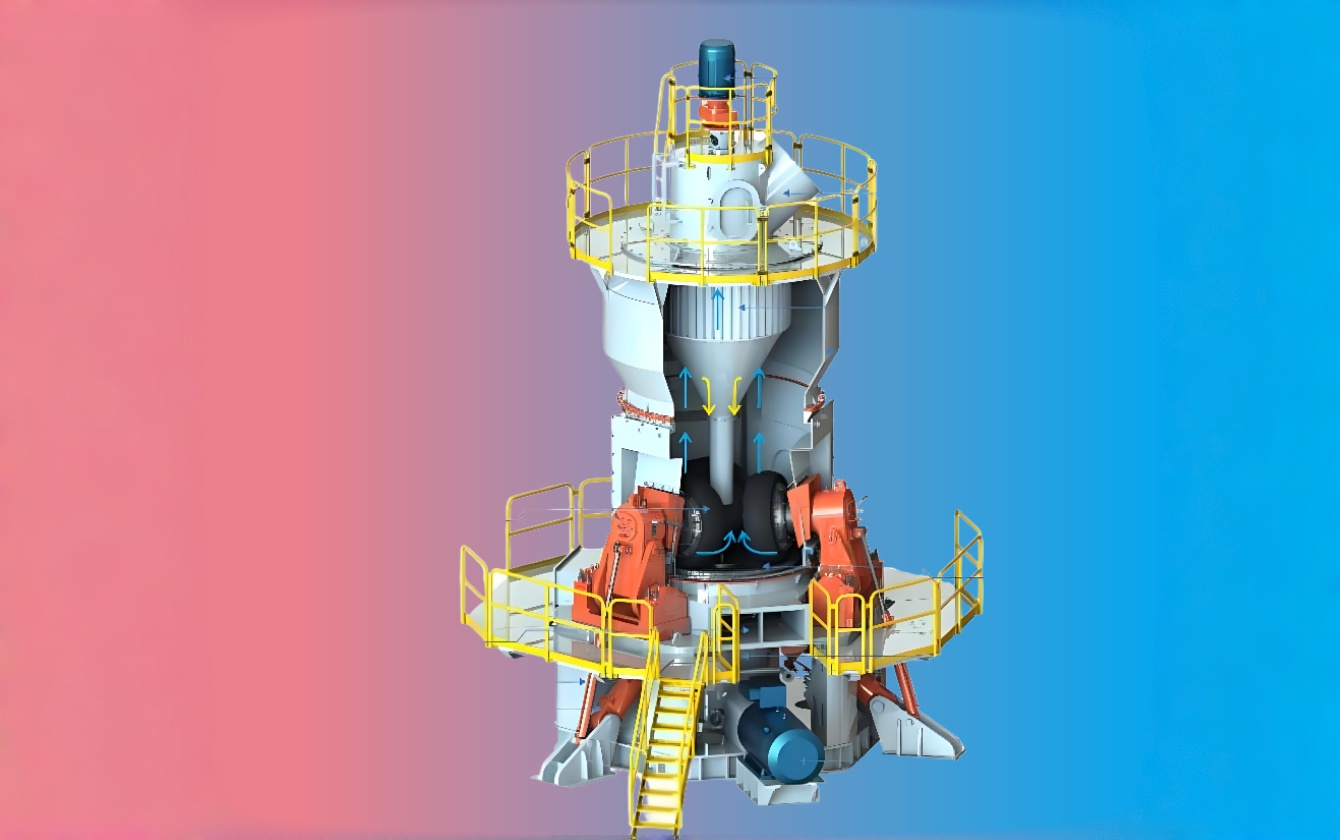

LVM Ultra-Fine Vertical Grinding Mill

This is a large-scale ultra-fine vertical grinding mill for mass production of ultra-fine grinding and processing of non-metallic minerals.

- Feed Size: ≤15mm

- Capacity: 20-100T/H

- Fineness: 80-325 mesh

Your Expert LVM Ultra-Fine Vertical Grinding Mill Supplier in China

The LVM Ultra-Fine Vertical Grinding Mill Device produced by Sandreck is suitable for large-scale ultra-fine grinding of various non-metallic minerals with Mohs hardness below 7 and moisture content below 6%, such as calcite, limestone, marble, heavy calcium, quicklime, talc, barite, dolomite, etc., in the industries of artificial granite, papermaking, coatings, PVC, wires and cables, rubber, pigments, etc.

Sandreck LVM Ultra-Fine Vertical Grinding Mill is a mill machine independently developed and designed by Sandreck Machinery based on many years of mill production experience. Our high quality grinding mill adopts the latest domestic and foreign grinding roller powder selection technology, integrates ultra-fine powder grinding, grading and transportation, and is the preferred product in the ultra-fine powder grinding industry.

LVM Ultra-Fine Vertical Grinding Mill Advantages

Under the same power, the efficiency is increased by 40% and the energy consumption is reduced by 70%.

The fineness of the final products can be adjusted arbitrarily between 325 mesh and 2500 mesh.

The grinding roller and liner are made of wear-resistant materials and have a long service life.

Equipped with a double limit device to protect the equipment from impact and vibration.

The PLC automatic control method is adopted to accurately control the grinding pressure.

The roller sleeve and liner are specially designed, which is easier to form a material layer than ordinary vertical mills.

Precise Grinding and High Particle Quality

Are you worried about having finsished products that are uneven or coarse? The Sandreck LVM Ultrafine Vertical Grinding Mill has an accurate classification system, adjustable D97 of 5-45μm,will provide you with high quality in your finished product regardless of whether you’re processing coatings or plastics!

Highly Efficient and Energy Saving

Worried about high energy costs? the Ultrafine Vertical Grinding Mill takes 30%-50% less energy than competitive equipment – the savings are staggering, leading to greater profitability with faster returns on your investment and a more economical operation

Robust Grinding Rollers And Rings

Worried about replacement parts and downtime? The grinding rollers and grinding discs in the LVM Ultrafine Vertical Grinding Mill are manufactured with a patented wear-resistant alloy, which has double the life expectancy of normal equipment. This means fewer replacement parts, reduced downtime, less worry and product durability for the long haul in production time.

How the LVM Ultra-Fine Vertical Grinding Mill Works

The Sandreck Ultra-fine Vertical Grinding Mill Features a “grinding-classifying-collection” integrated design and is a highly effective, energy-efficient, and precise ultrafine powder processing equipment.

Feeding and Drying

The feeder feeds the material into the grinding disk of the ultrafine vertical grinding mill while also simultaneously drying the highly humid material with hot air to process it together for the subsequent ultrafine grinding of the base material.

Grinding and Drying

The dried material falls onto the rotating grinding disk and is flinged to the outer edge due to centrifugal force. The hydraulic force that pressurizes the grinding roller grinds the bed of material while hot air carries the fine particles upwards.

Classification and Screening

The pulverized powder is drawn up by airflow into the high precision classifier. It controls the velocity exactly so that qualified fine powder (5 – 45μm, for example) can be collected by airflow while coarse powder drops back onto the grinding disk for further grinding.

Finished Product Collection

Eligible fine powder undergoes a pulse dust collection; the finished collects and the cleaned airflow expels. The entire operation is under negative pressure to ensure environmental and dust-free operation.

Golden Service

For your Vertical Compound Crusher equipments, we stand by your side 24 hours a day, providing round-the-clock protection for your choices!

Sandrek possesses extensive manufacturing facilities and a highly skilled R&D team, enabling us to provide you with Ultra-Fine Vertical Grinding Mills that deliver stable performance, exceptional durability, and robust reliability. This ensures your production requirements are fundamentally met.

You can first trial grind your material for free before you purchase the Ultra-Fine Vertical Grinding Mill. We create a solution that is exclusively geared to your requirements to link your requirements to the appropriate equipment and the maximum productivity.

We offer normal installation and commissioning services that include engineers to assist in start-up operations and provide adequate operator training guidance so that you can experience results as quickly as possible.

We also offer 24- 7 online service support and expedited shipment on spare parts with regular follow-up maintenance to turn your issues around quickly

More About Our Company

- Technical Parameters

Specifications | LVM15-3X | LVM16-3X | LVM17-3X |

| Main Motor Power (KW) | 220-280 | 315-400 | 355 – 450 |

| Fan Power (KW) | 180-200 | 250-280 | 325 – 355 |

| Power x Number of Multi-Head Powder Selectors | 15KW x6 | 22KW x6 | 22KW x 8 |

| Grinding Material Size (mm) D90 | <10, max 15mm | <10, max 15mm | <10, max 15mm |

| Moisture Content of Materials Entering The Mill | <3% | <3% | <3% |

| Grinding Roller Quantity (pcs) | 3 | 3 | 3 |

| D30, 2μm Output (t/h) | 9-12 | 12-16 | 14-18 |

| D45, 2μm Output (t/h) | 5.5-7.5 | 7-9 | 10-12 |

| D60, 2μm Output (t/h) | 3-4 | / | / |

Testimonials

We have a professional production team and can deliver within 20 working days after the contract is signed.

When using LVM ultra-fine vertical grinding mill, ensuring that the material properties are suitable, perform regular maintenance and lubrication, monitor the operating status, and gradually add materials after no-load start to avoid full-load operation.

The grinding rollers and grinding discs of ultra-fine vertical mill are usually replaced every 6-12 months, and the bearings are replaced every 1-2 years.

We are a mill factory in China, and each unit is ex-factory price. You can leave a message via WhatsApp (+8613666293477), and we will contact you as soon as possible.