50-80-T/H Stone Crushing Plant Overview

This 50-80-T/H Stone Crushing Plant scheme designed by Sandreck Mining Machinery is tailor-made for small and medium-sized sand and gravel plants, stone processing, and construction waste recycling projects. Under standard conditions with raw material moisture ≤8%, the maximum production capacity can reach 85 tons per hour.

Conventional Aggregate Specifications: 0-5mm, 5-10mm, 10-20mm, 20-31.5mm, etc.

High-hardness Rocks: such as granite, basalt, pebbles, iron ore, limestone, etc.

Medium to Low Hardness Materials: such as coal gangue, shale, tailings, construction waste concrete, bricks, etc.

Core Equipment Configuration for the 50 T/H Stone Crushing Plant

Feeding:

GZD9638 vibrating feeder (1 unit) – pre-screening and soil removal, uniform feeding.

Primary crushing: PEV500×750 Jaw Crusher (1 unit) – provides stable primary crushing for the entire line.

Secondary medium/fine crushing: PF1210 Impact Crusher (1 unit) – excellent product particle shape, suitable for most materials.

(For high-hardness rocks like granite or basalt, it can be replaced with an HST100 Cone Crusher for stronger wear resistance and lower operating costs.)

Screening and grading: 3YZS1860 triple-layer circular vibrating screen (1 unit) – efficient and precise screening.

Conveying: Customized belt conveyors (5–6 units) – connecting each process step.

Value-added options:

For producing manufactured sand, add a VSI7615 sand-making machine.

For high-standard clean aggregates, add a sand washer.

For construction waste processing, add iron removers at the entrance of each equipment unit.

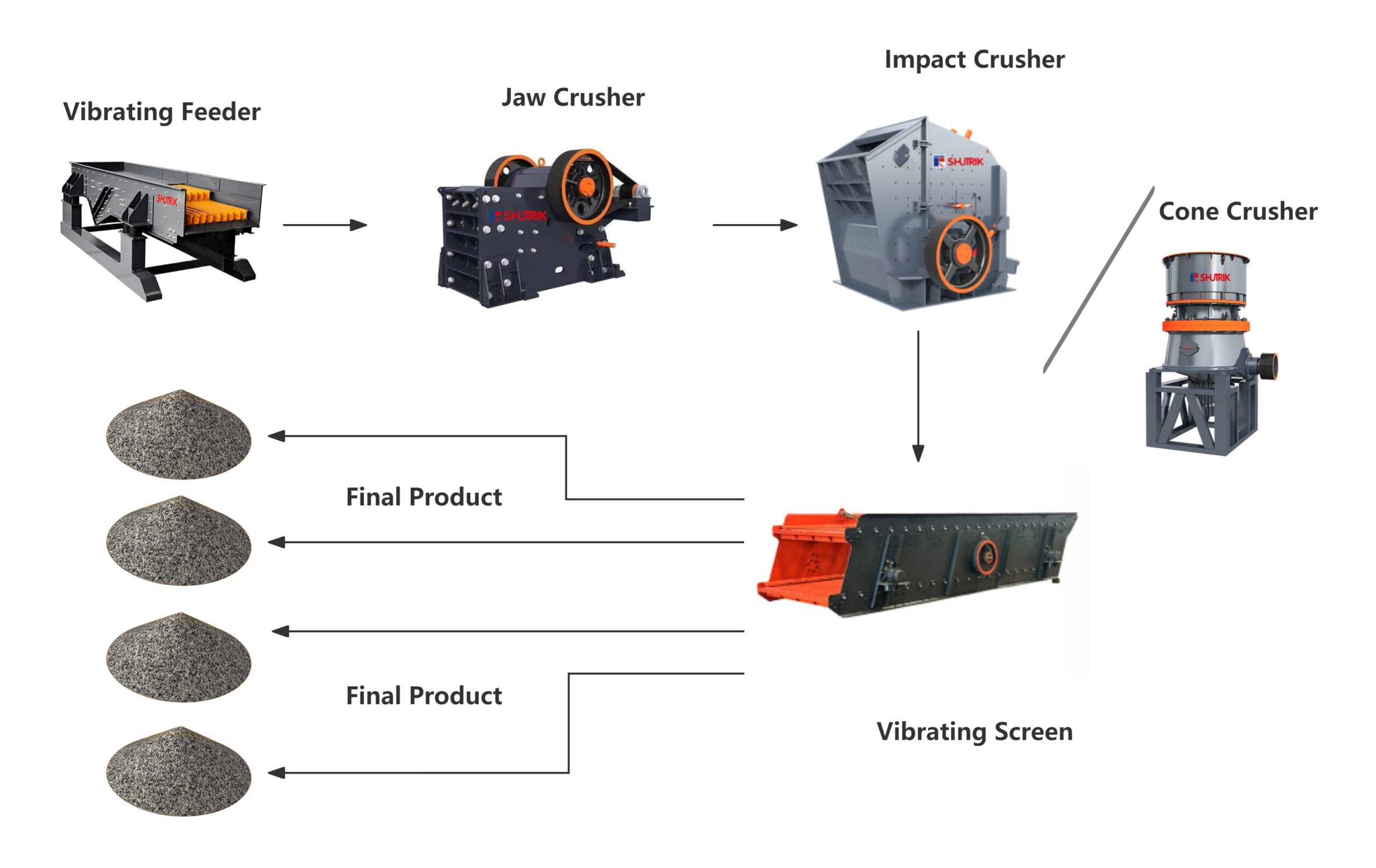

How the 50 T/H Stone Crushing Plant Works

The entire stone crushing line adopts automated production with minimal labor requirements, ensuring smooth operation:

Feeding and coarse crushing: Raw materials are evenly fed into the Jaw Crusher via the vibrating feeder for initial crushing, producing aggregates <150mm.

Fine crushing and shaping: The coarsely crushed materials enter the Impact Crusher (or Cone Crusher for hard rocks) for secondary crushing and shaping, producing aggregates ≤40mm.

Screening: The crushed materials are precisely screened by the multi-layer vibrating screen. Qualified finished products are directly sent to storage, while unqualified aggregates are returned to the Impact Crusher or Cone Crusher for re-crushing, forming a closed-loop cycle.

Optional washing: If needed, the screened finished products can be washed in a sand washer to obtain high-purity aggregates.

Core Advantages of Choosing the 50–80 T/H Crushing Plant Solution

- We have extensive project experience, and our crushing plants offer a stable production capacity of 50-80 T/H.

- Our crushing and shaping equipment features optimized designs, producing well-shaped aggregates and manufactured sand with a reasonable gradation.

- The key crushing components of our crushers and sand making machines utilize proprietary wear-resistant alloy materials, extending their service life by more than 30%.

- The entire production line features a modular design, suitable for both stationary and mobile configurations.

- A standard intelligent centralized control system is included, allowing for easy operation by only 2-3 people.

- Every piece of equipment we sell is supplied at factory price, resulting in a low investment threshold and a quick return on investment within 8-14 months.

Case Studies

Case 1: Limestone Sand-Making Production Line in Sichuan, China, with an Hourly Output of Approximately 70 Tons

Project Overview: The raw material is limestone, with a feed size of ≤210mm. The required finished product is 0-5mm sand, with an hourly output of approximately 75 tons.

Equipment Configuration: PE250×1200 Jaw Crusher ×2 + PF11214 Impact Crusher + VSI7615 Sand-Making Machine + 2YK2160 Vibrating Screen + XSD2610 Sand Washer + Multiple Conveyors.

Process Features:

1.Utilizing the site’s elevation differences, a modular design was adopted to rationally layout the production line.

2.The VSI Crusher is recommended as the sand-making machine, producing sand with an aesthetically pleasing grain shape.

Case 2: Granite Crushing and Sand-Making Production Line in Indonesia, Southeast Asia

Project Overview: The raw material is granite, with a feed size of ≤280mm. The stable hourly output is 50-80 tons, producing 0-5mm manufactured sand, 5-12mm, and 12-25mm aggregates, which must meet local infrastructure material standards.

Equipment Configuration: PE57 Jaw Crusher + HST100 Cone Crusher + 2YK1860 Vibrating Screen + Sand Washer + Conveyors.

Process Features and Advantages:

1.Due to site constraints, a Mobile Crushing Station was used, requiring minimal foundation work and facilitating easy relocation.

2.For high-hardness granite, the combination of a Jaw Crusher and a Cone Crusher is recommended, offering high crushing efficiency and low operating costs.

3.The inclusion of a sand washer ensures the finished product has a mud content of ≤1% after cleaning, meeting the requirements for construction sand.

Case 3: Limestone Aggregate Crushing Production Line in Ghana, Africa

Project Overview: The raw material is limestone rock, with a feed particle size of ≤350mm. There is no sand-making requirement. The stable hourly output after commissioning is 60-80 tons.

The finished products are three types of crushed stone aggregates: 5-10mm, 10-20mm, and 20-30mm, supplied directly to local municipal road and commercial housing construction projects.

Equipment Configuration: PE250×1000 Fine Jaw Crusher + CS600 Cone Crusher + 2YK1860 Vibrating Screen + 5 units of B650 Belt Conveyors.

Process Features:

1.The combination of a Jaw Crusher and a Cone Crusher is well-suited to the characteristics of limestone, providing a high crushing ratio and uniform output.

The dry screening process requires no water washing, making it suitable for the arid climate of Africa.