Sand Making Machine Factory

Sand making machine is a kind of crushing equipment specially used to produce sand and stone suitable for construction from various hard rocks and ores.

![]() Infrastructure fields such as construction, highways, railways, etc.

Infrastructure fields such as construction, highways, railways, etc.

![]() For the production of aggregates in water conservancy and hydropower projects.

For the production of aggregates in water conservancy and hydropower projects.

![]() For efficient sand production in concrete mixing stations and municipal engineering fields.

For efficient sand production in concrete mixing stations and municipal engineering fields.

Your Expert Sand Making Machine Supplier in China

Sandreck is a Sand Making Machine manufacturer and a well-known Sand Making Equipment source supplier in China. Our Sand Making Machines are are divided into VSI Sand Making Machines, Roller Sand Making Machines, Vertical Compound Crushers and other series and models, which can meet all the sand making needs of your project.

Sandreck Sand Making Machine is a commonly used cheap price Sand Making Equipment, designed to crush large pieces of materials into sand particles. Whether you are using it for railways, roads, construction waste recycling or bridges, energy, water conservancy, chemicals and other industries, our equipment can process ore into high-quality sand and gravel aggregates.

Sandreck professional design team not only focuses on the structural optimization of the high quality Sand Making Machine, but also on the durability of the Sand Making Equipment. Our Sand Making Machine parts are all made of high manganese steel and high wear-resistant materials to save you investment costs.

Product By Features

Crushing, sand making and shaping can be done by one machine.

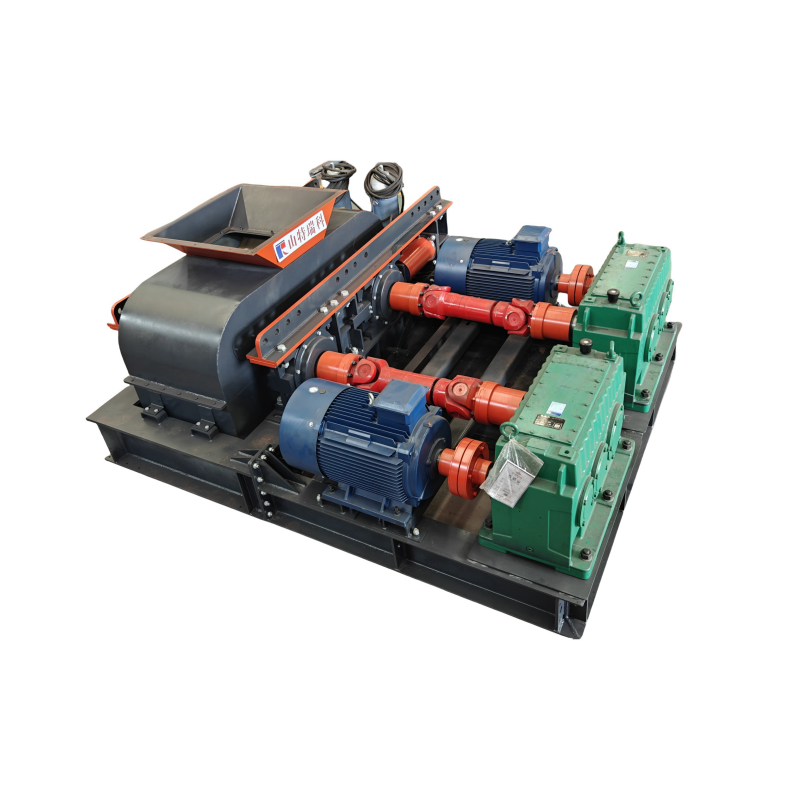

Sandreck Double Roller Crusher is suitable for fine crushing of stones with a finished particle size of 0-5mm.

The crushing ratio is large and the feed particle size can reach 100mm.

Sandreck Sand Making Machine Advantages

High crushing efficiency, good machine-made sand grain shape, meeting high-standard sand requirements.

Equipped with PLC hydraulic control system, simple operation and maintenance, saving operating costs.

The whole set of equipment is made of high manganese steel, with less wear and increased service life.

There are many types of low piece sand making machines to meet the various needs of your projects.

We will tailor professional sand making solutions for you according to your needs.

Sandreck adheres to the principle of Customes First and provides after-sales service throughout the year.

Why Choose Sandreck Sand Making Machine?

Sandreck is a Sand Making Machine factory which has more than 20 years of production experience, and is a well-known Sand Making Machine manufacturer at home and abroad. All Sand Making Machine has passed the ISO9001 international quality certification system standard certification and is sold to more than 150 countries and regions around the world, providing help for thousands of sand and gravel processing plants.

What Materials Can Sandreck Sand Making Machines Be Used For?

Our Sand Making Machines can be used for a variety of aggregates including river pebbles, bluestone, iron ore, basalt, granite, limestone and construction waste.

Custom, right-fit solutions

We do not just provide sand production equipment; we provide sand production solutions.

Our engineers analyze the essential parameters, including your raw material properties (hardness, soil content, and abrasiveness), target particle shape and gradation, expected production capacity, and investment amount. We analyze this data and design an optimized system for the entire process of crushing, shaping, and screening.

We will provide each solution with the best balance of production capacity, energy consumption, and investment to give you a customized sand production solution that works effectively, efficiently, with stability, and maximizes returns.

One Machine With Multiple Uses And Flexible Configuration

SANDRECK sand making machines provide high flexibility: If the feed size ≤ 4mm, it can crush and shape rock independently. Larger feed sizes require a full crushing and screening production line of jaw crushers, cone crushers, etc., for high output quality and equipment efficiency.

The jaw crusher performs the coarse crushing of bulk materials, optimizing the feed to the sand making machine to be appropriately qualified.

The cone crusher performs the secondary crushing of hard rock following coarse crushing, optimizing particle particle size for the sand making machine.

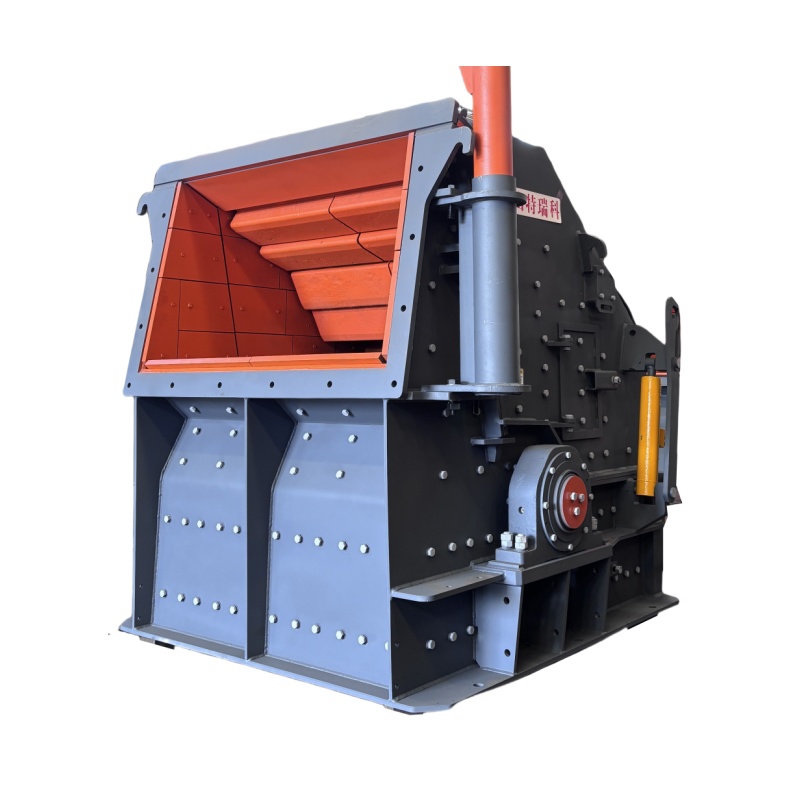

The impact crusher performs secondary and fine crushing of materials and shape particles for the sand making machine, establishing the foundation of the finished product’s quality.

Sand Making Machine Cases

Sandreck is a well-known mining machinery supplier in China and has successfully served over 1,000 sand and gravel plant projects, providing them with crushing and sand making solutions.

Processing material: Granite

Capacity: 300 t/h

Finished size: <5mm

Processing material: Basalt

Capacity: 300 t/h

Finished size: 0-3mm,3-5mm,5-10mm,10-20mm,20-31.5mm

Processing material: Basalt

Capacity: 50t/h

Finished size: <5mm

Processing material: Pebble

Capacity: 50t/h

Finished size: <5mm

Testimonials

We are a Chinese Sand Making Machine manufacturer. Each equipment is ex-factory price. You can leave a message via WhatsApp (+8613666293477) and we will contact you as soon as possible.

We need to always pay attention to the operating parameters, product particle size and output of the sand making machine. If any abnormality is encountered, stop the machine immediately to check and troubleshoot.

Different models of sand making machines have different prices, generally around US$70,000. The above prices are for your reference only.

The service life of the sand making machine depends on your daily maintenance and use time. For specific maintenance details, please consult the website customer service hotline and leave a message.

Related Product

Linear feeding equipment that continuously feeds materials into the crusher.

Used for grading and screening of minerals, quarries, building materials, etc.

Cone Crusher is suitable for sand and gravel aggregate production, mining operations.

Mobile sand making machine

This is more accurately described as a mobile sand making system than a single sand making machine.

The main sand making machines (such as impact, hammer, and double-roll crushers) are integrated with the feeding device, vibrating screen, conveyor belt, and other auxiliary equipment onto the same mobile chassis, forming a complete mobile unit.

Features:

- Flexibility is the main advantage of mobile sand making machines.

- They require no fixed foundation and can be transported directly to the front lines of mines or near construction waste dumps, facilitating product use.

- Lower transportation costs and shorter installation time.

How to Choose the Right Sand Making Machine for You?

Choosing the right sand making machine can avoid issues like insufficient production capacity or substandard products later.

Step 1: Precisely Define Your Needs

The core is to clarify your production conditions and goals, including the hardness and properties of the material to be processed, the desired hourly production capacity, the particle shape and gradation standards for the finished sand, and a comprehensive consideration of the budget for equipment purchase and long-term maintenance.

Step 2: Preliminary Screening and Equipment Matching

Based on the needs from Step 1, preliminarily identify the suitable type of equipment.

For example, if pursuing high-quality commercial concrete sand, an Impact Sand Making Machine is the preferred choice; if dealing with scattered construction waste, a Mobile Sand Making Plant is the best solution

Step 3: Scrutinize Key Performance Indicators

Focus on hard parameters like the equipment’s throughput capacity, feed size, power, and rotational speed. At the same time, be sure to investigate the material and service life of the core wear parts, as these directly determine your long-term operating costs and equipment stability.

Step 4: Evaluate the Manufacturer’s Comprehensive Strength

Look beyond the equipment itself and assess the supplier’s “soft power”. Confirm whether the equipment’s environmental protection and intelligent level meet standards, and strictly examine their after-sales service system, including installation support, technical training, and spare parts supply speed.

Sand Making Machine: Proper Use and Maintenance

After the selection of the right sand making machine, its correct use and maintenance are necessary for regular working and durability.

Application:

The high grade of manufactured sand made in the sand making machines finds a ready market in built-or-concrete, dry-mix mortar, asphalt concrete, railway ballast and irrigation work

Scientific Production Line Configuration:

It is remembered that the sand making machine is but a member of the production line. It is necessary for it to work in perfect harmony with other processes such as “crushing” – “secondary crushing” – “screening” – “dressing with sand” to produce maximum effects. A proper production line configuration is essential.

Routine Maintenance: (Main points)

- Frequent Inspection: To note all bearings temperature, and abnormal noise levels, or vibration before startup daily.

- Emphasis Maintenance: Lubricate regularly as per hand book, especially main shaft bearings.

- Earlier Replacement: To be ever watchful of the parts likely to wear out and replace them on the q.t. to avoid “small jobs developing into large evils.