Sand Washing Machine

The Sandreck Sand Washing Machine is an industrial machine that utilizes advanced water-washing technology to professionally remove surface impurities from sand and gravel, significantly improving material quality.

Our Sand Washer utilizes a water flow and mechanical agitation system to achieve two core functions:

![]() Efficiently separate dirt, dust, and other impurities from sand and gravel.

Efficiently separate dirt, dust, and other impurities from sand and gravel.

![]() Completely decomposes the water vapor layer on the sand’s surface, creating favorable conditions for subsequent dehydration.

Completely decomposes the water vapor layer on the sand’s surface, creating favorable conditions for subsequent dehydration.

Your Expert Sand Washing Machine Manufacturers In China

Sandreck is a professional Sand Washing Equipment Manufacturer in China. Our Sand Washing Machines have high efficiency against high mud content sand natural and manufactured.

Sandreck Sand Washing Machines are specially designed against difficult materials like river sand and tailings. In gravel production lines, they can accurately remove clay, dust and other impurities from crushed aggregate material.

With various equipment specifications and professional customized modification, we can provide the most suitable Sand Washing solutions for sand-gavel plants, batching plants and all kinds of engineering projects.

Our Integrated Tailings Recovery Machine are paired with Spiral Sand Washing Machines and Wheel Sand Washing Machine. All our machines come in various sizes so you can easily choose your model which matches your required production needs.

Product By Features

Sandreck Sand Washing Equipment plays a key role in the sand and gravel purification process. We offer complete Sand Washing system solutions

Spiral Sand Washing Machine

Spiral Sand Washing MachineThe synergistic effect of impeller tumbling and water flushing achieves deep cleaning of sand and gravel.

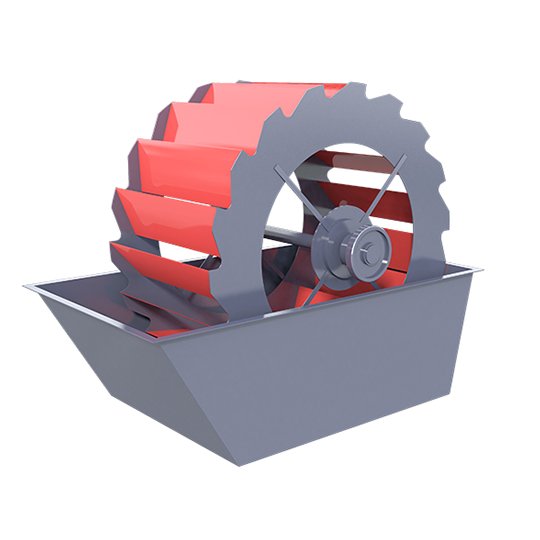

Wheel Sand Washing Machine

Wheel Sand Washing MachineThe spiral blades promote frictional cleaning of the material, combining cleaning, dehydration, and classification.

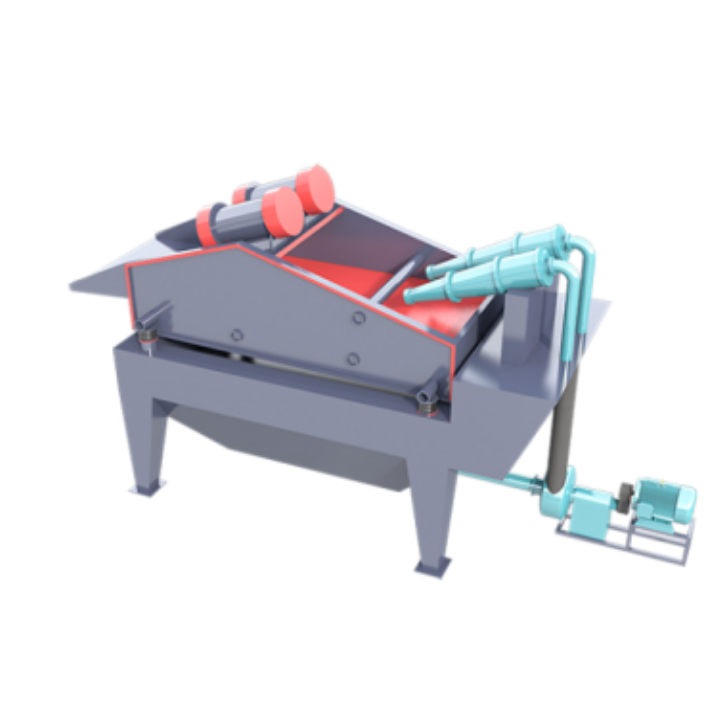

Integrated tailings recovery machine

Integrated tailings recovery machineIntegrated cyclone concentration and dehydration screening efficiently recover fine sand lost in Sand Washing wastewater.

Sand Washing Machine Advantages

The impeller/spiral structure and water flow quickly remove surface impurities, enhancing the cleanliness of the finished product.

There are corresponding models for medium and fine sand, high mud coarse sand or site-limited scenes in this machine.

Some configurations have water circulation systems, and wastewater is reused after filtration to reduce resource consumption.

Sandreck Sand Washing Machine reduces sand loss, the screen of it intercepts fine sand so that its recovery rate is high.

The steel frame and wear-resistant parts ensure long-term operation, and the protective cover reduces the risk of failure.

Sandreck is a source manufacturer, there is no middlemen taking profits, our machine’s price is the lowest price in the worldwide.

How To Choose The Suitable Sand Washing Machine?

If your raw material is coarse sand with high mud content, then Sandreck Spiral Sand Washing Machine is your best choice. The long tank design prolongs the cleaning time and has high cleanliness, which is suitable for your large-scale production line.

If you pursue efficient cleaning, then Sandreck Wheel Sand Washing Machine is your ideal choice. The impeller design can reduce the sand loss rate and is suitable for processing medium and fine sand.

Closed-Loop Water Circulation System

Sandreck Sand Washers integrated design gives an efficiency of 95% in water resource recycling, resulting in a water consumption as low as 0.5 tones per ton of sand. The annual saving for you is in excess of 120,000 tones of water and total elimination of any environmental risk.

Sand Washing Equipment Linkage Work

Pretreatment

If the mud content of materials is high, a Spiral Sand Washer is used; if the mud content is low, a Wheel Sand Washer is used.

The coarse sand (≥0.3 mm) produced in the pre-washing process is used as finished sand, and wastewater (containing fine sand ≤0.3 mm) is sent to the tailings recovery machine.

Recycling

The Integrated Tailings Recovery Machine is equipped with a hydrocyclone for splitting the fine sand, which is dewatered in a dewatering machine and is mixed with the coarse sand, thus producing finished sand.

The purified water from the Integrated Tailings Recovery Machine is then fed back into the sand washing machine. Therefore, no wastewater is generated.

Spiral Sand Washing Machine + Integrated Tailings Recovery Machine: Spiral sand Washing Machines produce a high loss of fine sand (5%-8%). A reclaimer can increase this recovery rate to over 98% and increase production by 10%-15%. This makes it suitable for coarse materials such as slag and weathered rock.

Wheel Sand Washing Machine + Integrated Tailings Recovery Machine: The wheel-type Sand Washing achine itself produces low fine sand loss (≤3%). The combined system primarily recovers trace amounts of fine sand and ensures wastewater recycling. This makes it suitable for concrete sand (where particle size is a high requirement) or for applications with stringent environmental requirements.

Customized services for sand washing machines from Sandreck

Special Sand Washing Machine configurations determined by the characteristics of the raw materials (clay content, grain size, etc.)

Advice on the Sand Washing Machines most suited to your production requirements from a technical, quantitative and economic point of view

Optimal layout and installation of the machines according to local

Equipping your sand washing installations with the most appropriate fine sand recovery and water circulation systems

Technical Parameters

- Spiral Sand Washing Machine

- Wheel Sand Washing Machine

- Case Picture

| Specifications | Spiral diameter (mm) | Effective length (mm) | Screw speed (r/min) | Output (t/h) | Matching motor (kw) | Number of spirals |

| LX1000 | 1000 | 6000 | 18 | 10-30 | 7.5 | 1 |

| LX1200 | 1200 | 6000 | 16 | 30-50 | 7.5-11 | 1 |

| LX1500 | 1500 | 6000 | 16 | 50-80 | 11-15 | 1 |

| 2LX1200 | 1200 | 6000 | 14 | 70-120 | 11×2 | 2 |

| 2LX1500 | 1500 | 6000 | 12 | 80-150 | 15×2 | 2 |

| Model | Impeller Specifications (mm) | Feed Size (mm) | Processing Capacity (t/h) | Speed (r/min) | Power (kw) | Motor Model | Dimensions (mm) |

| XSD2610 | Φ2600*1000 | 10 | 20-60 | 1.178 | 7.5 | Y160L-8/7.5 | 3255x1982x2690 |

| XSD3016 | Φ3000*1600 | 10 | 70-120 | 1.179 | 8-15 | Y200L-8/15 | 3845x3000x3080 |

Testimonials

Sandreck is a Sand Washing Machine manufacturer, integrating manufacturing, production and supply in one. We have a professional after-sales team, there are original parts to provide, maintenance costs are very low.

Sandreck have a dedicated production team. The delivery time of our Sand Washing Machine is generally made within 20 days after the contract is signed.

You can send us a message on WhatsApp(+86 13666293477) or leave your contact details on our website or click here, later our online customer service will contact you and offer the price of our Sand Washing Machine.

Related Products

Adopts V-shaped cavity design, used for coarse and medium crushing of stones.

Adopts laminated crushing principle and is equipped with multiple crushing chambers.

Feed size 4mm, with the function of crushing, sand-making, and shaping in one machine

Used in large-scale stone quarries, ore sorting, coal screening and chemical raw materials.